Auto Parts Categories and Applications: Understanding the Essential Components of Automotive Systems

The automotive industry comprises a wide range of auto parts, each with specific functions and applications. Understanding the various categories of auto parts, their components, and the automotive systems they belong to is essential for businesses involved in the auto parts sector. This article provides a detailed overview of auto parts categories, their components, and their applications in different types of vehicles.

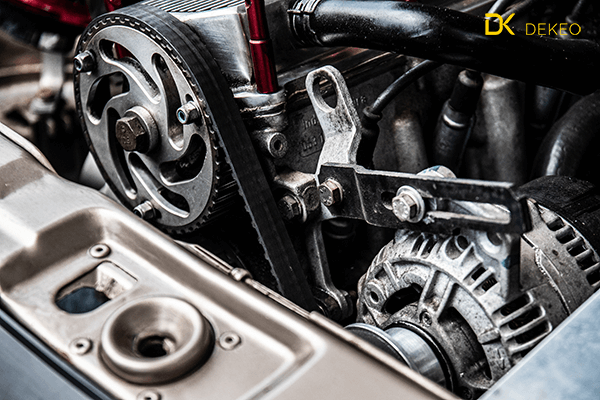

Engine components are the heart of a vehicle, ensuring optimal performance and efficiency. Some key engine components include:

- Spark plugs: Responsible for igniting the air-fuel mixture in the combustion chamber.

- Fuel injectors: Deliver precise amounts of fuel to the engine.

- Timing belts: Coordinate the opening and closing of engine valves with the movement of pistons.

- Radiators: Help maintain the engine's temperature by dissipating heat.

These components are crucial for the proper functioning of various engine types, such as gasoline, diesel, and electric.

- Transmission System

The transmission system transfers power from the engine to the wheels, allowing the vehicle to move. Key components of the transmission system include:

- Clutches: Enable smooth gear shifting and power transfer between the engine and transmission.

- Gearboxes: Contain various gears that enable the vehicle to operate at different speeds.

- Drive shafts: Transmit torque from the transmission to the wheels.

- Differentials: Distribute power evenly to the wheels, allowing them to rotate at different speeds when needed.

Transmission components are applicable to manual, automatic, and continuously variable transmissions (CVTs).

- Suspension and Steering Systems

Suspension and steering systems provide stability, control, and comfort while driving. Essential components of these systems include:

- Shock absorbers: Absorb and dampen road shocks to ensure a smooth ride.

- Springs: Support the vehicle's weight and help maintain proper ride height.

- Control arms: Connect the wheels to the vehicle's frame and enable vertical movement.

- Tie rods: Transmit steering input from the steering gear to the wheels.

These components are vital for various vehicle types, including passenger cars, trucks, and off-road vehicles.

The braking system is crucial for vehicle safety, allowing the driver to slow down or stop the vehicle. Key braking system components include:

- Brake pads: Create friction with the brake rotors to slow down or stop the vehicle.

- Brake rotors: Disc-shaped components that brake pads press against to create friction.

- Brake calipers: House the brake pads and apply force to the brake rotors.

- Brake master cylinders: Convert brake pedal input into hydraulic pressure for the brake system.

Braking system components are applicable to various brake types, such as disc, drum, and regenerative braking systems.

- Electrical System

The electrical system powers various vehicle functions, such as lighting, ignition, and infotainment. Key electrical system components include:

- Alternators: Generate electricity to power the vehicle's electrical components and charge the battery.

- Batteries: Store electrical energy for starting the engine and powering electrical accessories.

- Starters: Engage the engine's flywheel to initiate the combustion process.

- Wiring harnesses: Transmit electrical signals and power throughout the vehicle.

These components are essential for all types of vehicles, regardless of their powertrain.

In conclusion, understanding the various categories of auto parts, their components, and their applications in different types of vehicles is vital for businesses involved in the auto parts sector. By staying informed about the essential components of automotive systems, businesses can better serve their customers and maintain a competitive edge in the industry.

- Posted in Automotive, Autoparts, Import, Industry, Supplier

Experience the thrill of flight and the fear of falling. The Fourth Wing PDF captures every heart-stopping moment of the book. Make sure you have the digital version ready for when you need an escape into fantasy. https://fourthwingpdf.top/ Fourth Wing Series

Учитесь у мастеров, вдохновляйтесь их работами и создавайте своё уникальное наследие https://artisanalcrafts.ru/

Ремесло – это когда вы создаёте не для продажи, а для радости https://artisanalcrafts.ru/

Хендмейд – это про любовь к процессу, а не к результату https://artisanalcrafts.ru/

Nicely put. Appreciate it!

real online casino ohio https://combatcasino.info/ethereum-casino/ online casino games malaysia