Auto Parts Categories and Applications: Understanding the Essential Components of Automotive Systems

The automotive industry comprises a wide range of auto parts, each with specific functions and applications. Understanding the various categories of auto parts, their components, and the automotive systems they belong to is essential for businesses involved in the auto parts sector. This article provides a detailed overview of auto parts categories, their components, and their applications in different types of vehicles.

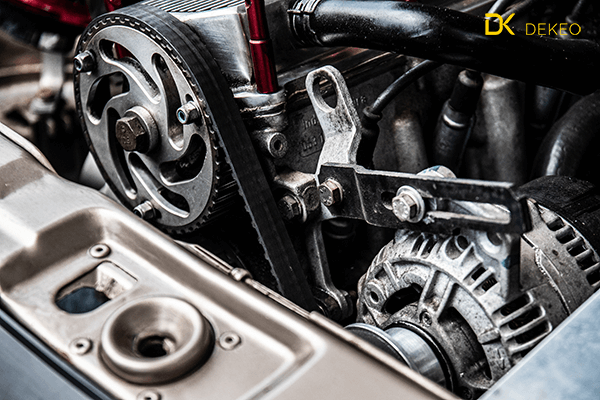

Engine components are the heart of a vehicle, ensuring optimal performance and efficiency. Some key engine components include:

- Spark plugs: Responsible for igniting the air-fuel mixture in the combustion chamber.

- Fuel injectors: Deliver precise amounts of fuel to the engine.

- Timing belts: Coordinate the opening and closing of engine valves with the movement of pistons.

- Radiators: Help maintain the engine's temperature by dissipating heat.

These components are crucial for the proper functioning of various engine types, such as gasoline, diesel, and electric.

- Transmission System

The transmission system transfers power from the engine to the wheels, allowing the vehicle to move. Key components of the transmission system include:

- Clutches: Enable smooth gear shifting and power transfer between the engine and transmission.

- Gearboxes: Contain various gears that enable the vehicle to operate at different speeds.

- Drive shafts: Transmit torque from the transmission to the wheels.

- Differentials: Distribute power evenly to the wheels, allowing them to rotate at different speeds when needed.

Transmission components are applicable to manual, automatic, and continuously variable transmissions (CVTs).

- Suspension and Steering Systems

Suspension and steering systems provide stability, control, and comfort while driving. Essential components of these systems include:

- Shock absorbers: Absorb and dampen road shocks to ensure a smooth ride.

- Springs: Support the vehicle's weight and help maintain proper ride height.

- Control arms: Connect the wheels to the vehicle's frame and enable vertical movement.

- Tie rods: Transmit steering input from the steering gear to the wheels.

These components are vital for various vehicle types, including passenger cars, trucks, and off-road vehicles.

The braking system is crucial for vehicle safety, allowing the driver to slow down or stop the vehicle. Key braking system components include:

- Brake pads: Create friction with the brake rotors to slow down or stop the vehicle.

- Brake rotors: Disc-shaped components that brake pads press against to create friction.

- Brake calipers: House the brake pads and apply force to the brake rotors.

- Brake master cylinders: Convert brake pedal input into hydraulic pressure for the brake system.

Braking system components are applicable to various brake types, such as disc, drum, and regenerative braking systems.

- Electrical System

The electrical system powers various vehicle functions, such as lighting, ignition, and infotainment. Key electrical system components include:

- Alternators: Generate electricity to power the vehicle's electrical components and charge the battery.

- Batteries: Store electrical energy for starting the engine and powering electrical accessories.

- Starters: Engage the engine's flywheel to initiate the combustion process.

- Wiring harnesses: Transmit electrical signals and power throughout the vehicle.

These components are essential for all types of vehicles, regardless of their powertrain.

In conclusion, understanding the various categories of auto parts, their components, and their applications in different types of vehicles is vital for businesses involved in the auto parts sector. By staying informed about the essential components of automotive systems, businesses can better serve their customers and maintain a competitive edge in the industry.

- Posted in Automotive, Autoparts, Import, Industry, Supplier

portable balancing machines

Portable Balancing MachinesThe realm of engineering and manufacturing benefits greatly from the use of portable balancing machines, which serve a crucial role in maintaining the efficiency and longevity of rotating machinery. These innovative devices are designed to identify and rectify imbalances in various rotors, including those found in engines, turbines, and even agricultural equipment. This summary delves into the significance, types, and applications of portable balancing machines, providing insights for enthusiasts and professionals alike.

Understanding Portable Balancing MachinesPortable balancing machines are invaluable tools engineered to address the technical challenges of rotor imbalance. They are compact and can be easily transported, enabling on-site balancing that minimizes operational downtime. Unlike their stationary counterparts, portable machines offer the flexibility needed in diverse working environments, ranging from factories to remote fields.

Why Use Portable Balancing Machines?Using a portable balancing machine not only enhances the performance of rotating equipment but also aids in prolonging the lifespan of components by reducing wear and tear caused by vibrations. This preventive maintenance tool enables businesses to avoid costly repairs and replacements, making it an essential investment.

Types of Portable Balancing MachinesThe design and function of portable balancing machines can vary widely, catering to specific balancing needs. Broadly, these machines can be categorized into two main types: soft bearing machines and hard bearing machines.

Soft Bearing MachinesSoft bearing machines utilize flexible supports to allow for natural oscillations during the balancing process. This flexibility allows for effective vibration absorption and is particularly beneficial when balancing rotors at lower speeds. These machines are often favored for their simplicity and manufacturability. Users can easily set up and achieve accurate results without extensive technical skills, making them ideal for smaller operations and DIY enthusiasts.

Hard Bearing MachinesIn contrast, hard bearing machines boast a more rigid structural design. The supports are designed to be robust, catering to a wider range of rotor sizes and weights. These machines are capable of high-precision balancing even at lower rotational speeds, providing versatility in demanding industrial applications. Though they are generally costlier and may require a higher level of expertise to operate, hard bearing machines deliver superior performance, making them suitable for professional settings where precision is paramount.

The Components of Portable Balancing MachinesThe efficacy of portable balancing machines lies in their well-engineered components. Key parts include:

Measuring Systems: These systems, comprising vibration sensors and phase angle sensors, play a pivotal role in detecting imbalance and determining corrective measures. Support Structures: The supports vary based on machine type, with soft bearing machines benefitting from flexible designs, while hard bearing machines utilize solid non-flexible components. Drive Mechanisms: The drive systems facilitate the rotation of the rotor during the balancing process, with varying degrees of speed control based on machine design. Applications of Portable Balancing MachinesPortable balancing machines find application across various industries, enhancing productivity and minimizing equipment breakdowns. Here are some key areas where these machines excel:

1. ManufacturingIn manufacturing environments, particularly where precision is crucial, portable balancing machines help ensure that rotating components, such as fans and rotors, function optimally, thus supporting overall operational efficiency.

2. AutomotiveThe automotive industry benefits from portable balancing machines for maintaining engines and drive shafts. Ensuring that these components are vibration-free leads to improved performance and reduced wear on vehicle parts.

3. AgricultureFarm equipment requires regular maintenance to operate at maximum efficiency. Portable balancing machines provide farmers with the ability to balance navigational equipment, augers, and other machinery directly in the field, saving time and resources.

4. Aerospace and AviationIn aerospace, precision is non-negotiable. Portable balancing machines can be used to maintain and repair rotors in aircraft and drones, ensuring safety and performance.

Choosing the Right Portable Balancing MachineSelecting the appropriate portable balancing machine depends on several factors, including the application, rotor characteristics, and required precision level. It’s essential to evaluate the specific needs of your operations and choose a machine that not only meets but exceeds those specifications. Expert consultation may provide further guidance in making an informed decision.

ConclusionPortable balancing machines are essential in maintaining the effectiveness and reliability of various rotors across multiple sectors. By investing in these machines, individuals and enterprises can prevent costly breakdowns, minimize downtime, and ensure the precision of their operations. Embrace the power of portable balancing machines, and empower your business to achieve exceptional performance and efficiency.