Categorías y aplicaciones de autopartes: comprensión de los componentes esenciales de los sistemas automotrices

La industria automotriz comprende una amplia gama de autopartes, cada una con funciones y aplicaciones específicas. Comprender las diversas categorías de autopartes, sus componentes y los sistemas automotrices a los que pertenecen es esencial para las empresas involucradas en el sector de autopartes. Este artículo proporciona una descripción detallada de las categorías de autopartes, sus componentes y sus aplicaciones en diferentes tipos de vehículos.

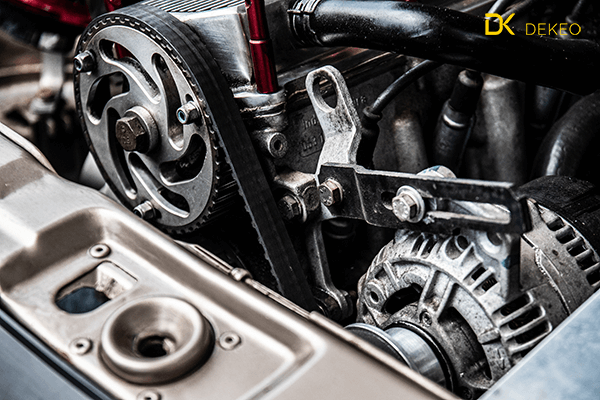

Los componentes del motor son el corazón de un vehículo y garantizan un rendimiento y una eficiencia óptimos. Algunos componentes clave del motor incluyen:

- Bujías : Encargadas de encender la mezcla aire-combustible en la cámara de combustión.

- Inyectores de combustible : Suministran cantidades precisas de combustible al motor.

- Correas de distribución : Coordinan la apertura y cierre de las válvulas del motor con el movimiento de los pistones.

- Radiadores: ayudan a mantener la temperatura del motor al disipar el calor.

Estos componentes son cruciales para el correcto funcionamiento de varios tipos de motores, como gasolina, diésel y eléctricos.

- Sistema de transmisión

El sistema de transmisión transfiere potencia del motor a las ruedas, lo que permite que el vehículo se mueva. Los componentes clave del sistema de transmisión incluyen:

- Embragues: permiten un cambio de marcha suave y una transferencia de potencia entre el motor y la transmisión.

- Cajas de cambios: contienen varios engranajes que permiten que el vehículo funcione a diferentes velocidades.

- Ejes de transmisión : Transmiten el par de la transmisión a las ruedas.

- Diferenciales: distribuyen la potencia uniformemente a las ruedas, permitiéndoles girar a diferentes velocidades cuando sea necesario.

Los componentes de transmisión son aplicables a transmisiones manuales, automáticas y continuamente variables (CVT).

- Sistemas de suspensión y dirección

Los sistemas de suspensión y dirección brindan estabilidad, control y comodidad durante la conducción. Los componentes esenciales de estos sistemas incluyen:

- Amortiguadores : absorben y amortiguan los impactos de la carretera para garantizar una conducción suave.

- Resortes : Soportan el peso del vehículo y ayudan a mantener la altura de manejo adecuada.

- Brazos de control : Conectan las ruedas al chasis del vehículo y permiten el movimiento vertical.

- Tirantes : transmiten la entrada de dirección desde el mecanismo de dirección a las ruedas.

Estos componentes son vitales para varios tipos de vehículos, incluidos turismos, camiones y vehículos todoterreno.

El sistema de frenado es crucial para la seguridad del vehículo, ya que permite al conductor reducir la velocidad o detener el vehículo. Los componentes clave del sistema de frenado incluyen:

- Pastillas de freno : crean fricción con los rotores de freno para reducir la velocidad o detener el vehículo.

- Rotores de freno : componentes en forma de disco contra los que presionan las pastillas de freno para crear fricción.

- Pinzas de freno: Aloja las pastillas de freno y aplica fuerza a los rotores de freno.

- Cilindros maestros de freno : Convierta la entrada del pedal de freno en presión hidráulica para el sistema de frenos.

Los componentes del sistema de frenos son aplicables a varios tipos de frenos, como los sistemas de frenos de disco, de tambor y regenerativos.

- Sistema eléctrico

El sistema eléctrico alimenta varias funciones del vehículo, como la iluminación, el encendido y el infoentretenimiento. Los componentes clave del sistema eléctrico incluyen:

- Alternadores : Generan electricidad para alimentar los componentes eléctricos del vehículo y cargar la batería.

- Baterías: Almacenan energía eléctrica para arrancar el motor y alimentar los accesorios eléctricos.

- Arrancadores : Accione el volante del motor para iniciar el proceso de combustión.

- Arneses de cableado : transmiten señales eléctricas y energía por todo el vehículo.

Estos componentes son esenciales para todo tipo de vehículos, independientemente de su sistema de propulsión.

En conclusión, comprender las diversas categorías de autopartes, sus componentes y sus aplicaciones en diferentes tipos de vehículos es vital para las empresas involucradas en el sector de autopartes. Al mantenerse informados sobre los componentes esenciales de los sistemas automotrices, las empresas pueden atender mejor a sus clientes y mantener una ventaja competitiva en la industria.

- Publicado en Automotive, Autoparts, Import, Industry, Supplier

You stated this perfectly!

online casino nederland ideal https://combatcasino.info/review-las-atlantis/ are there any legitimate online casinos

Thanks. Valuable stuff.

arizona casino online https://combatcasino.info/real-money-online-casino-indiana/ legal gambling online casino

Nicely put, Thank you.

live casino gambling online https://buckscasino.info/states/ online casino with bank transfer

Enhancing Machinery Maintenance with Balanset-1A: Field Balancing ServicesWatch YouTube Short

In the world of machinery maintenance and repair, achieving optimal performance and longevity is crucial. One of the key processes in ensuring this is rotor balancing, a practice that reduces vibration, extends equipment life, and enhances efficiency. Enter the Balanset-1A by Vibromera, a sophisticated tool designed to streamline and perfect the rotor balancing process.

Understanding the Rotor Balancing Process with Balanset-1AThe Balanset-1A offers a comprehensive solution for rotor balancing, involving several meticulous steps from preparation to correction. Here’s a closer look at the process:

Preparation of EquipmentStart by positioning the vibration sensors perpendicular to the rotor’s axis of rotation. Secure a laser tachometer on a magnetic stand, aiming it at a reflective tape attached to the rotor’s pulley. Connect the sensors to the Balanset device and link it to a laptop via USB. Launch the Balanset software and select the two-plane balancing mode.

Initial Vibration MeasurementPrior to balancing, weigh a test load and document its weight and installation radius. Run the rotor to measure the initial vibration levels, determining the amplitude and phase of the inherent imbalance.

Balancing in the First PlaneInstall the test load in the first balancing plane, corresponding to the location of the first sensor, and operate the rotor to measure vibration levels. A change of at least 20% in amplitude or phase indicates partial correction of imbalance.

Balancing in the Second PlaneNext, transfer the test load to the second plane where the second sensor is installed. Run the rotor again and take measurements. These data points will aid the software in calculating the precise position and weight of corrective loads.

Correcting ImbalanceBased on the collected data, the Balanset software will suggest corrective weights and their installation angles for both planes. Remove the test load and prepare the corrective weights according to the software’s recommendations, installing them at the specified angle relative to the test load’s original position.

Verification and CompletionFinally, operate the rotor to verify the balance. If the vibration is reduced to an acceptable level, the process is complete. If further correction is needed, the software will provide additional guidance on where and how much weight to install.

Features and Benefits of Balanset-1AThe Balanset-1A boasts several features that make it an invaluable tool for field balancing:

Compact and portable, perfect for on-site work. Intuitive software with step-by-step instructions. Functions as both a vibrometer and balancing device. High precision measurements suitable for various industrial applications. Customizable options for specific tasks and requirements. Easy to learn and use, even for beginners in vibration diagnostics. Supports serial balancing for repetitive tasks. Can be used without a tachometer for quick diagnostics. ConclusionWith a competitive price of 1751 euros, the Balanset-1A offers an excellent balance of cost and quality. Its design caters to both large-scale industrial operations and smaller workshops, making it a smart investment for anyone looking to enhance their machinery maintenance and repair processes.

Contact Information:

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on Amazon

Balanset-1A OEM on Machinio

vibration monitoring equipment

Vibration monitoring equipment plays a significant role in enhancing the efficiency and longevity of machinery across various industries. The Balanset-1A, a state-of-the-art portable balancer and vibration analyzer, embodies the essence of this technology. It is specifically engineered to perform dynamic balancing on a vast array of rotors, including those found in crushers, fans, mulchers, augers on combines, shafts, centrifuges, and turbines. Its versatility makes it an essential tool for maintenance professionals aiming to ensure optimal performance in their operations.

Equipped with two channels, the Balanset-1A is designed for dynamic balancing in two planes. This advanced feature allows for highly precise balancing that mitigates vibration issues, optimizing machinery performance across multiple applications. Its comprehensive capabilities make it an invaluable asset for industries reliant on various rotating equipment.

The Balanset-1A includes a broad range of functionalities necessary for rotor balancing and vibration analysis. One of its key features is the Vibrometer Mode, which accurately measures rotational speed (RPM) and determines the phase angle of vibration signals. This precision is critical in diagnosing issues and facilitating corrective actions to enhance machine reliability.

In addition, the Balanset-1A provides detailed analysis through its FFT (Fast Fourier Transform) Spectrum capability. This feature delivers a granular view of the frequency spectrum of vibration signals, enabling users to identify and address specific vibration characteristics that could indicate underlying problems within the machinery.

Monitoring overall vibration levels is another essential function of the Balanset-1A. By tracking these values, operators can gain insights into the condition and performance of machinery, allowing for proactive maintenance practices that prevent costly failures. The Measurement Log feature further supports this by storing measurement data for future analysis, providing a historical perspective on equipment performance and facilitating trends tracking.

The balancing modes available in the Balanset-1A are designed to meet diverse operational requirements. The device supports both single-plane balancing and two-plane balancing, accommodating different rotor types and configurations. The Polar Graph feature visually depicts the imbalance, guiding technicians in accurately placing weights to achieve optimal balance.

This intelligent system also offers a Tolerance Calculator, which adheres to ISO 1940 standards to compute acceptable balancing tolerances. This adherence to international standards ensures that equipment consistently operates within acceptable limits, minimizing unplanned downtime and maintenance costs.

Moreover, the Balanset-1A supports balancing grinding wheels using three counterweights, highlighting its multifunctional design. The system also offers various charting capabilities, providing visual representations of overall vibration data, harmonic frequencies, and fundamental frequency components. These visual tools make it easier for users to interpret data and make informed decisions based on the condition of their equipment.

In terms of specifications, the Balanset-1A is equipped with two vibration sensors (vibro accelerometers) with cable lengths of 4 meters, along with an optional extension of 10 meters. The Laser Tachometer facilitates precise speed measurement within a distance range of 50 to 500 mm, enhancing the accuracy of the overall monitoring process. These components work seamlessly to provide reliable and actionable insights.

The software integration of the Balanset-1A is another key facet of its design. It allows users to measure vibration, calculate the necessary corrections, and analyze phase angles effectively. The USB interface module enables easy connection to a PC, providing a user-friendly interface for data management and reporting.

This portable vibration monitoring equipment is not just about functionality; it also prioritizes user convenience. The ability to archive previous balancing sessions and generate detailed reports of balancing outcomes empowers users to streamline their maintenance processes. This capability not only enhances workflow efficiency but also fosters a culture of continuous improvement within organizations that utilize the equipment.

Furthermore, with options to work in both imperial and metric systems, the Balanset-1A ensures compatibility with varying industrial standards globally. This adaptability is crucial for businesses operating on an international scale, where equipment must align with different measurement systems.

The importance of vibration monitoring equipment like the Balanset-1A cannot be overstated. In an era where industrial efficiency is paramount, having reliable tools for monitoring and analyzing machinery performance is essential. The Balanset-1A provides a comprehensive solution for businesses seeking to optimize their operations, reduce maintenance costs, and enhance the lifespan of their equipment.

In summary, the Balanset-1A portable balancer and vibration analyzer represents a major advancement in vibration monitoring equipment. Its multifaceted capabilities make it an invaluable asset for any industry that relies on rotating machinery. By ensuring precise dynamic balancing and offering in-depth analysis of vibration signals, the Balanset-1A helps maintain operational efficiency, reduce downtime, and uphold the highest standards of performance across diverse applications.

Embracing such advanced vibration monitoring equipment equips organizations with the tools necessary to thrive in today’s competitive landscape. By investing in reliable technology like the Balanset-1A, companies can achieve greater productivity, safety, and efficiency in their operations, ultimately leading to sustainable growth and success.