Categorías y aplicaciones de autopartes: comprensión de los componentes esenciales de los sistemas automotrices

La industria automotriz comprende una amplia gama de autopartes, cada una con funciones y aplicaciones específicas. Comprender las diversas categorías de autopartes, sus componentes y los sistemas automotrices a los que pertenecen es esencial para las empresas involucradas en el sector de autopartes. Este artículo proporciona una descripción detallada de las categorías de autopartes, sus componentes y sus aplicaciones en diferentes tipos de vehículos.

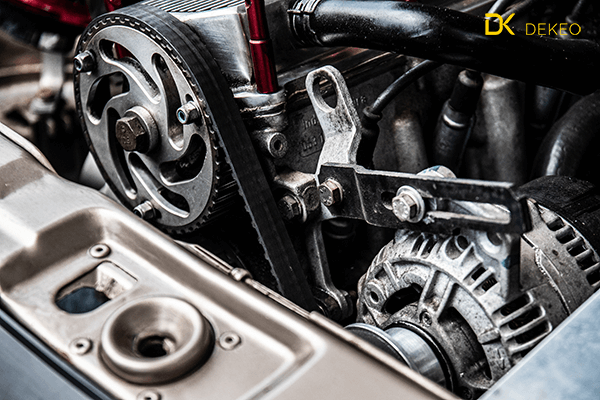

Los componentes del motor son el corazón de un vehículo y garantizan un rendimiento y una eficiencia óptimos. Algunos componentes clave del motor incluyen:

- Bujías : Encargadas de encender la mezcla aire-combustible en la cámara de combustión.

- Inyectores de combustible : Suministran cantidades precisas de combustible al motor.

- Correas de distribución : Coordinan la apertura y cierre de las válvulas del motor con el movimiento de los pistones.

- Radiadores: ayudan a mantener la temperatura del motor al disipar el calor.

Estos componentes son cruciales para el correcto funcionamiento de varios tipos de motores, como gasolina, diésel y eléctricos.

- Sistema de transmisión

El sistema de transmisión transfiere potencia del motor a las ruedas, lo que permite que el vehículo se mueva. Los componentes clave del sistema de transmisión incluyen:

- Embragues: permiten un cambio de marcha suave y una transferencia de potencia entre el motor y la transmisión.

- Cajas de cambios: contienen varios engranajes que permiten que el vehículo funcione a diferentes velocidades.

- Ejes de transmisión : Transmiten el par de la transmisión a las ruedas.

- Diferenciales: distribuyen la potencia uniformemente a las ruedas, permitiéndoles girar a diferentes velocidades cuando sea necesario.

Los componentes de transmisión son aplicables a transmisiones manuales, automáticas y continuamente variables (CVT).

- Sistemas de suspensión y dirección

Los sistemas de suspensión y dirección brindan estabilidad, control y comodidad durante la conducción. Los componentes esenciales de estos sistemas incluyen:

- Amortiguadores : absorben y amortiguan los impactos de la carretera para garantizar una conducción suave.

- Resortes : Soportan el peso del vehículo y ayudan a mantener la altura de manejo adecuada.

- Brazos de control : Conectan las ruedas al chasis del vehículo y permiten el movimiento vertical.

- Tirantes : transmiten la entrada de dirección desde el mecanismo de dirección a las ruedas.

Estos componentes son vitales para varios tipos de vehículos, incluidos turismos, camiones y vehículos todoterreno.

El sistema de frenado es crucial para la seguridad del vehículo, ya que permite al conductor reducir la velocidad o detener el vehículo. Los componentes clave del sistema de frenado incluyen:

- Pastillas de freno : crean fricción con los rotores de freno para reducir la velocidad o detener el vehículo.

- Rotores de freno : componentes en forma de disco contra los que presionan las pastillas de freno para crear fricción.

- Pinzas de freno: Aloja las pastillas de freno y aplica fuerza a los rotores de freno.

- Cilindros maestros de freno : Convierta la entrada del pedal de freno en presión hidráulica para el sistema de frenos.

Los componentes del sistema de frenos son aplicables a varios tipos de frenos, como los sistemas de frenos de disco, de tambor y regenerativos.

- Sistema eléctrico

El sistema eléctrico alimenta varias funciones del vehículo, como la iluminación, el encendido y el infoentretenimiento. Los componentes clave del sistema eléctrico incluyen:

- Alternadores : Generan electricidad para alimentar los componentes eléctricos del vehículo y cargar la batería.

- Baterías: Almacenan energía eléctrica para arrancar el motor y alimentar los accesorios eléctricos.

- Arrancadores : Accione el volante del motor para iniciar el proceso de combustión.

- Arneses de cableado : transmiten señales eléctricas y energía por todo el vehículo.

Estos componentes son esenciales para todo tipo de vehículos, independientemente de su sistema de propulsión.

En conclusión, comprender las diversas categorías de autopartes, sus componentes y sus aplicaciones en diferentes tipos de vehículos es vital para las empresas involucradas en el sector de autopartes. Al mantenerse informados sobre los componentes esenciales de los sistemas automotrices, las empresas pueden atender mejor a sus clientes y mantener una ventaja competitiva en la industria.

- Publicado en Automotive, Autoparts, Import, Industry, Supplier

Twisted Love is a book that demands to be read in one sitting because the suspense is just that high. The romance is steamy, but the emotional connection is what truly resonates. Many fans suggest grabbing the Twisted Love PDF if you want to highlight the most poignant passages. Alex’s possessiveness is a central theme, framed within the context of his traumatic past. Ava’s growth from a sheltered girl to a strong woman is equally important. Together, they create a story that is both heart-wrenching and heartwarming.

The sheer popularity of Twisted Love is a testament to its quality. It taps into universal themes of love, loss, and redemption. Many new readers look for the Twisted Love PDF to see what the fuss is about. The story of Alex and Ava is iconic in the romance community. It is a book that delivers exactly what it promises: a twisted, beautiful, and unforgettable love story. https://twistedlovepdf.site/ Twisted Love Pdf En Español Descargar

If you love a hero who grovels when he messes up, you will appreciate the ending of this book. Alex has to earn Ava back. The Twisted Love PDF is often sought after for this specific sequence. The redemption arc is well-handled. It is a story that satisfies the desire for justice and love in equal measure. https://twistedlovepdf.site/ Twisted Love Pdf Drive

The writing in Twisted Love is evocative and sensory. You can smell the rain and feel the cold of Alex’s apartment. Digital readers love the Twisted Love PDF for the immersive experience. The author creates a mood that is unique to this series. It is a book that pulls you in and doesn’t let go. https://twistedlovepdf.site/ Twisted Love De Ana Huang Pdf

The contrast between Alex’s dark wardrobe and Ava’s colorful life is a visual metaphor for their relationship. They bleed into each other’s worlds. Reading the Twisted Love PDF brings this imagery to life. The book is full of such symbolic details. It is a rich, textured reading experience. https://twistedlovepdf.site/ Ana Huang Twisted Love Pdf